The Importance of Manufacturing Technicians in Industry

Manufacturing technicians use various technologies to set up and test machinery used in the industry. They also monitor production equipment to ensure quality and efficiency.

The manufacturing industry is an essential part of economic progress, which is why technicians are such an important addition. There is a lot that goes into manufacturing in general, from sourcing the correct materials (quality steel tubing for automotive manufacturing), to conducting preventative maintenance on crucial machines.

These careers have become more popular as technological advances allow factories to produce more and more products quickly. These changes have sparked an ability gap in many production jobs, but a few things can be done to close it.

Job Duties

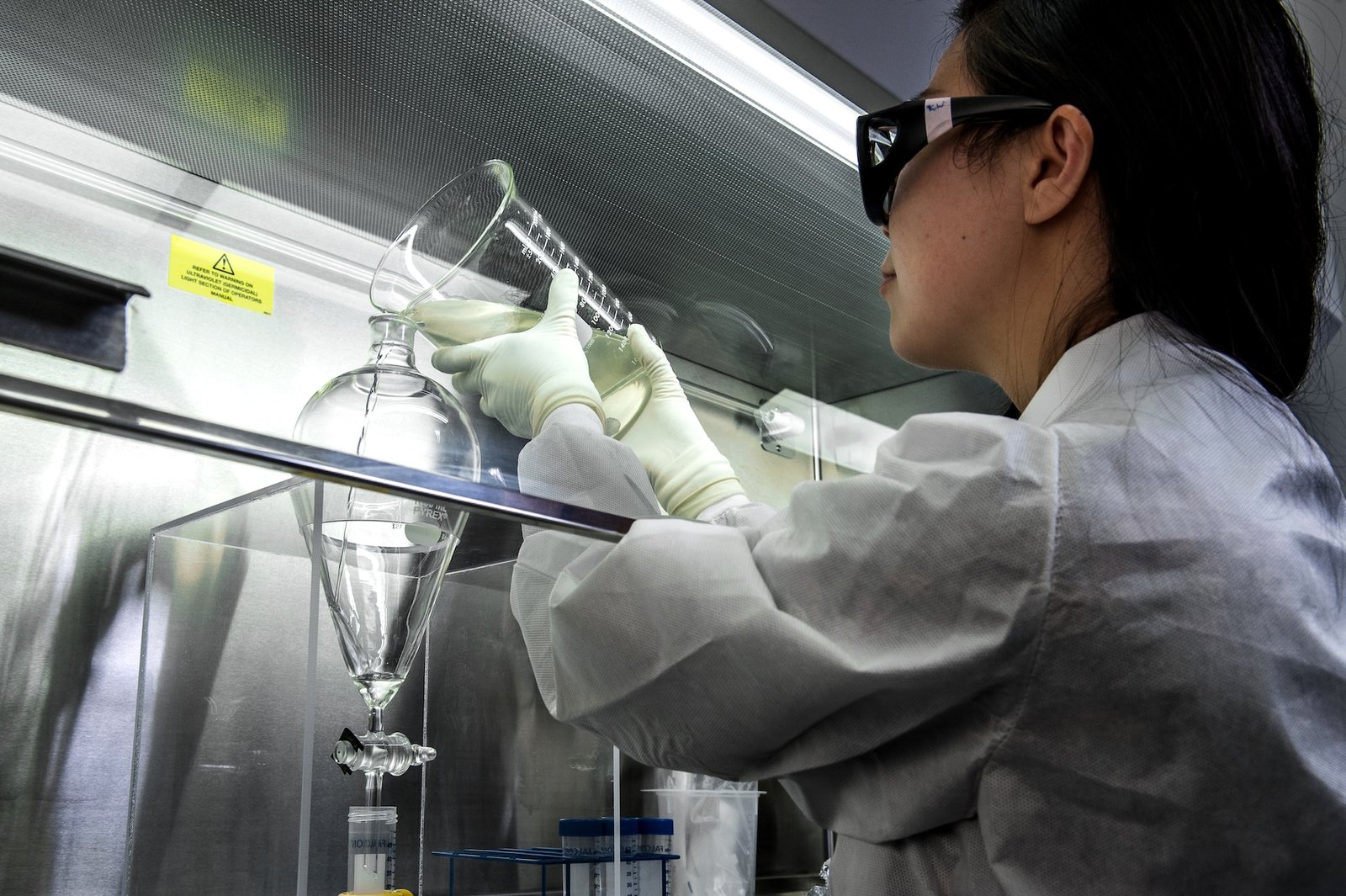

Manufacturing technicians, like GMP manufacturing technicians, use their technical skills to inspect and test equipment, materials, or assemblies used in production. They also perform minor preventative maintenance tasks to keep machines in good working order.

Their job duties vary depending on the type of manufacturing plant they work in. They may operate machine tools, computer numerical control (CNC) mills, robots, and welding equipment.

They are responsible for maintaining a clean and safe workplace. They regularly work with hazardous chemicals, so personal protective gear such as hand protection and proper eye protection are required.

They set up and adjust machinery or equipment to ensure quality production using tools such as calipers, micrometers, height gauges, or ring gauges. They also test and monitor finished products to ensure they meet customer specifications. They adhere to all applicable health, safety, and environmental regulations. They also help engineers develop, build, or test prototypes or new products, processes, or procedures.

Education and Training Requirements

Manufacturing technicians need a variety of educational and training qualifications to ensure they can perform their job duties correctly. They must have technical skills to operate equipment and solid problem-solving abilities to troubleshoot production issues.

Depending on the field they’re working in, a technician will specialize in different skills and equipment. For instance, a hyperboloid connector supplier will typically work with military and aerospace firms, which requires a specific set of technical abilities. Technicians should understand which industries they want to work in before they start training.

They must also have organizational skills to manage all of their work. This includes keeping track of inventory, maintaining production schedules, and performing other tasks that affect the quality of products.

Typically, production technicians earn an associate’s degree in manufacturing technology or a related field. They also may participate in trade union apprenticeship programs, which can last four years and include on-the-job and classroom training.

As automation becomes more common in factories, many manufacturing companies seek workers to operate and maintain these machines. This means that production technicians must be able to understand the software and how it works. Additionally, they must stay up-to-date on the latest manufacturing trends, including robotics.

Work Environment

The work environment for manufacturing technicians in the industry can be challenging. They are exposed to noise, dust, and fumes and may have to work in awkward positions.

They often work long hours, including on weekends and evenings. Some are required to travel to different plants and sites to complete their work.

Typical job duties include monitoring production equipment and creating maintenance logs and reports per company protocol. Some also perform quality control inspections and other production processes, using their problem-solving skills to solve any problems during production.

A high-quality manufacturing plant promotes a work culture that nurtures employees and treats them as more than just laborers. This motivates them to provide their best at work and increases their satisfaction with the job. The plant is also likely to have adequate compensation and other benefits, which help keep employees motivated.

Safety and Protective Equipment

Manufacturing technicians work in environments where safety is a top priority. Exposure to hazardous chemicals, airborne particles, and loud machinery means proper protective gear is essential. Depending on the specific workplace hazards, technicians may need gloves, eye protection, hearing protection, or respiratory equipment to stay safe on the job.

In settings where airborne contaminants or insufficient ventilation pose a risk, using a papr respirator can provide reliable respiratory protection. These powered air-purifying respirators help ensure a steady supply of clean air, reducing the risk of inhaling harmful particles while maintaining comfort during long shifts.

Employers typically provide safety training to ensure workers understand how to use protective equipment correctly. Following workplace safety protocols not only helps prevent injuries but also improves overall efficiency and productivity in manufacturing environments.

Salary

Manufacturing technicians play a critical role in the industry. They operate industrial equipment, perform work processes, and ensure their products meet quality standards.

The salary of a manufacturing technician varies depending on the specific job duties and the industry they work in. In the automotive, computer and electronics, and medical device industries.